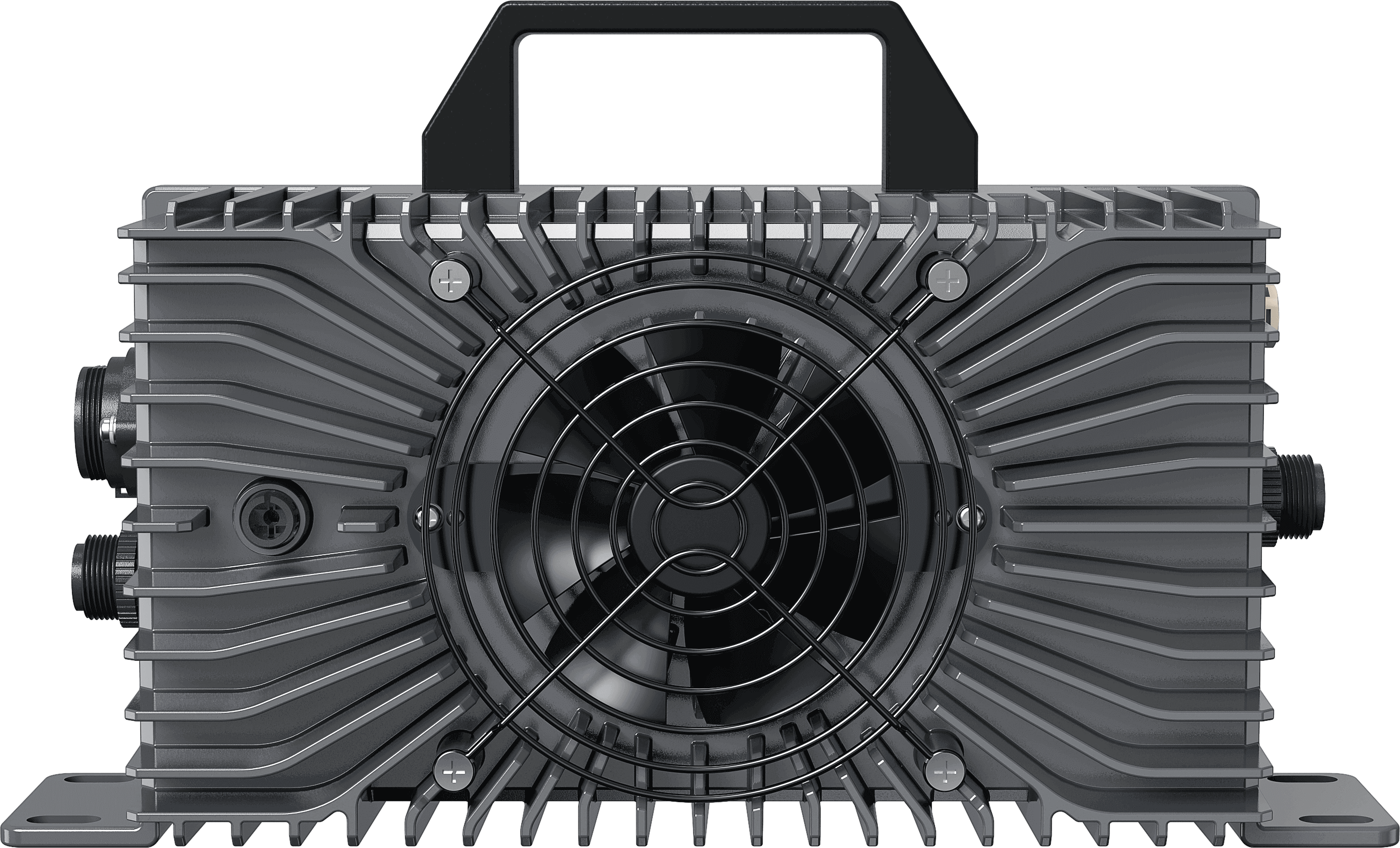

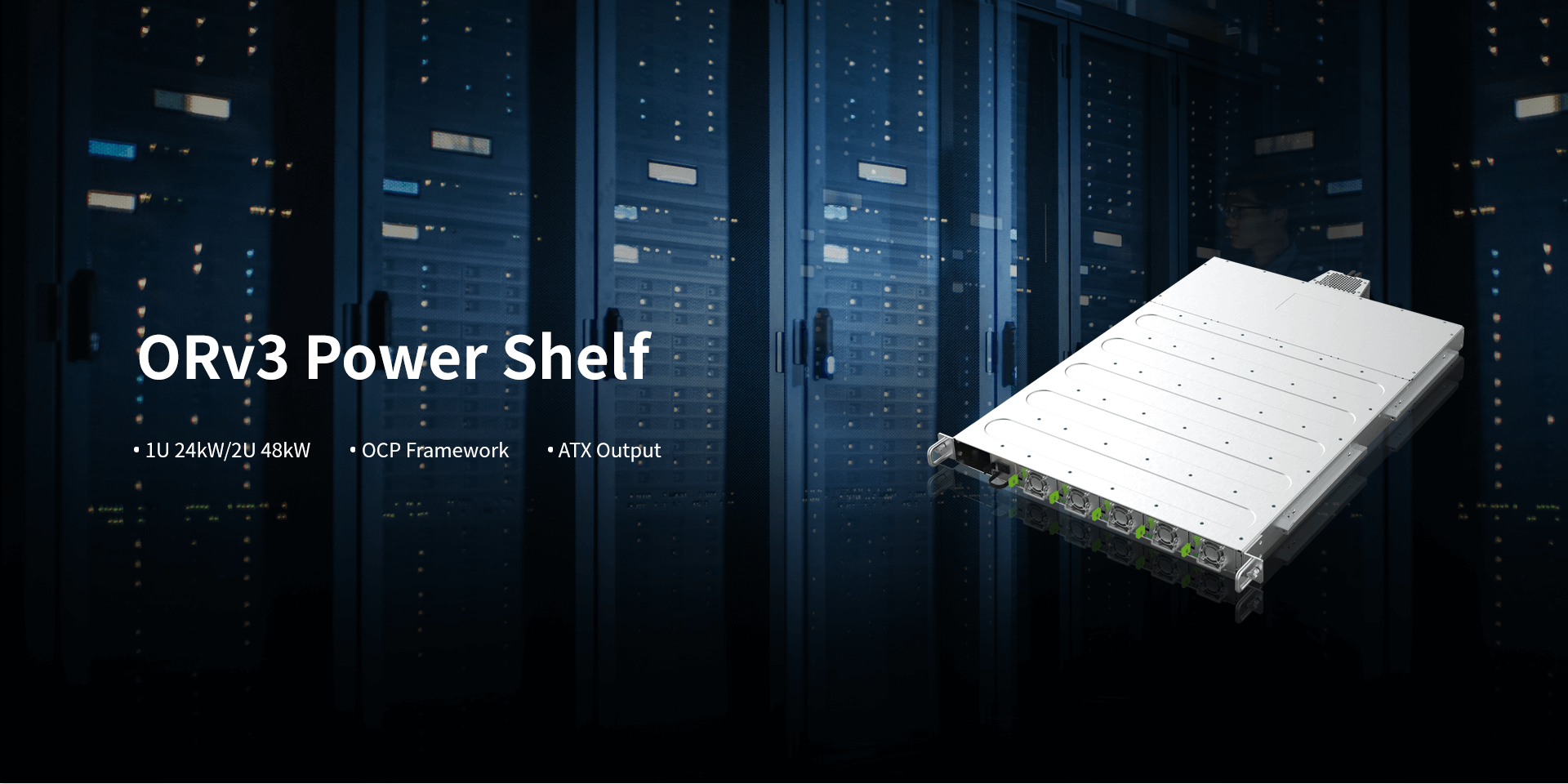

Big Data

Big Data

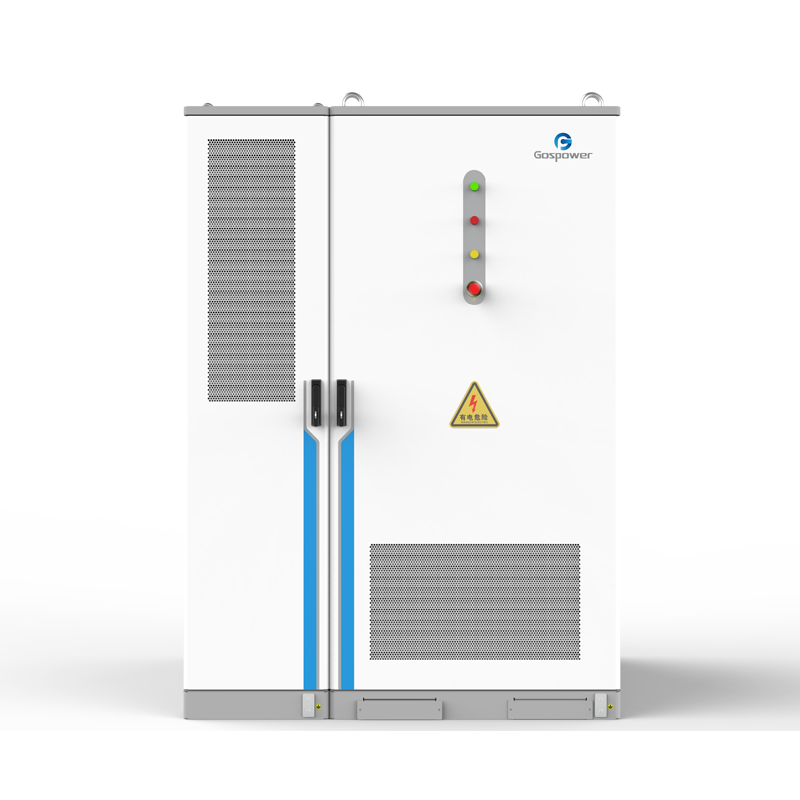

New Energy

New Energy

Committed to Providing Digital Power Solutions for Big Data and New Energy Industries

Big data and new energy are the foundations of our dual business ecosystem. Gospower is committed to be the global leading digital power solutions provider.

18 years

Industry Experience

400 +

R&D Engineers

120,000 ㎡

Factory Floor Space

100 million +

Cumulative Shipment

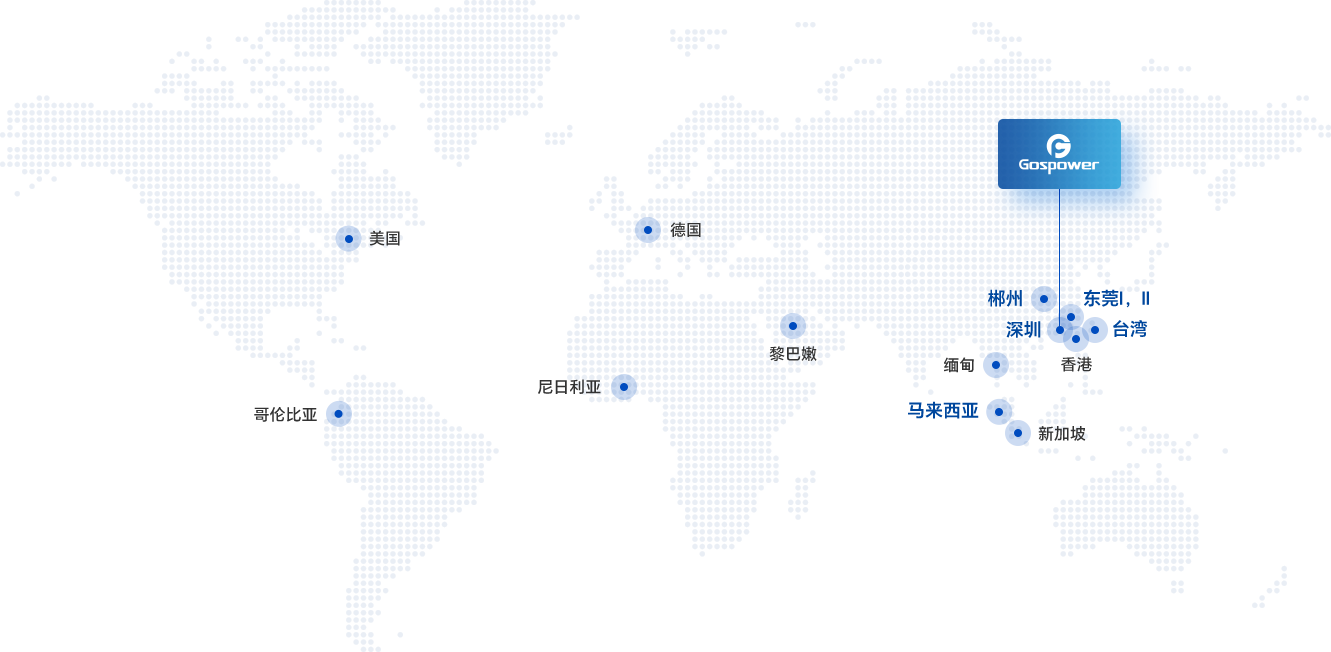

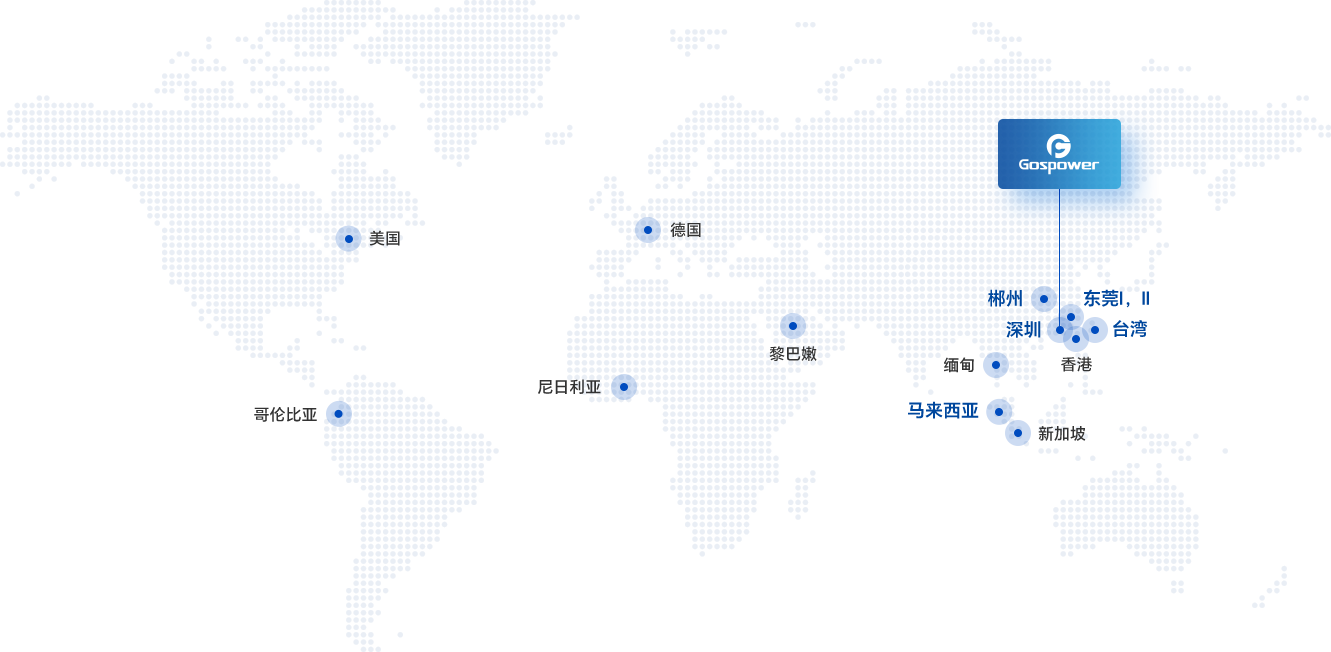

Global Layout

America

Colombia

Germany

Nigeria

Lebanon

Burma

Malaysia

Singapore

Chenzhou

Shenzhen

Hong Kong

Taiwan

Dongguan

- R&D Center:

Shenzhen Taiwan Malaysia

- Manufacturing Base:

Dongguan Malaysia Chenzhou

- Branches/Offices:

USA Germany Singapore Myanmar Nigeria Lebanon Colombia Taiwan Hong Kong

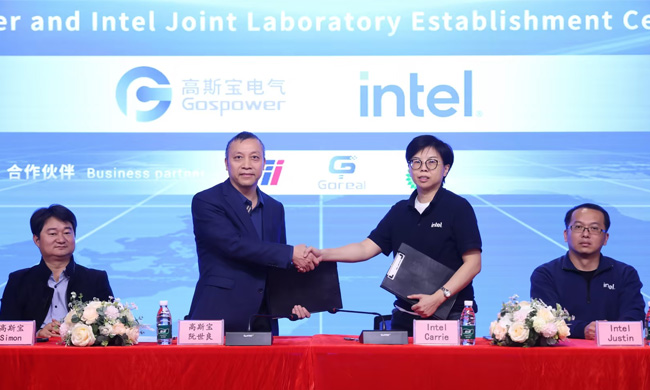

News

2025-03-12

Gospower Showcases Immersion Cooling AI Power Solutions at Intel 2025 SuperFluid Advanced Cooling Community Conference